The development of sewage treatment

Wherever people live there is sewage. The advanced civilisations in the Middle East and China already acknowledged the problem of waste water treatment and built drainage systems in order to lead dirty water out of their cities. The construction of the vast sewerage network in ancient Rome with its central element, the cloaca maxima, was state of the art in the fifth century BC and the peak of sewage treatment in antiquity. With the decline of the Roman Empire, however, this knowledge was lost. In the Middle Ages, cities literally drowned in human waste. The common practice of simply disposing of household refuse in the streets repeatedly caused raging epidemics. The Industrial Revolution in the 19th century exacerbated the waste water problem – not only because the rapidly growing towns produced previously unheard-of quantities of waste water but also because, for the first time in human history, this sewage contained large amounts of toxic residue from industrial processes. In the metropolitan area of the Ruhr region, for instance, these pressing problems led to the foundation of the Ruhrverband in 1913.

In England, the powerhouse of industrialisation, the Rivers Pollution Prevention Act was passed as early as 1876 as the first cohesive body of laws on sewage treatment. Preference was initially given to natural irrigation techniques which were later developed into artificial biological processes. Irrigation was also seen as a convenient method of fertilisation. Consciously utilising the self-purifying capacity of water was also considered a natural cleaning process. In North America, discharging sewage into a body of water was called "cleaning by dilution".

Mechanical treatment

Around the turn of the last century, mechanical sewage treatment was developed. It was widely implemented in Germany, the main target being to aesthetically clean the sewage before discharging it into a body of water. Mechanical methods include screens which remove large pollutants from the water much like a sieve or a rake.

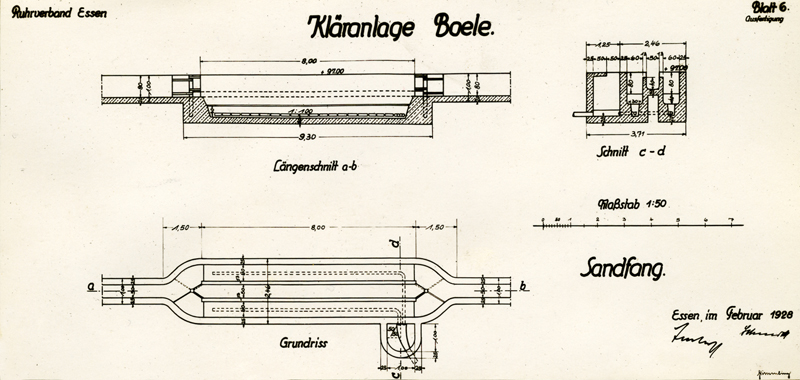

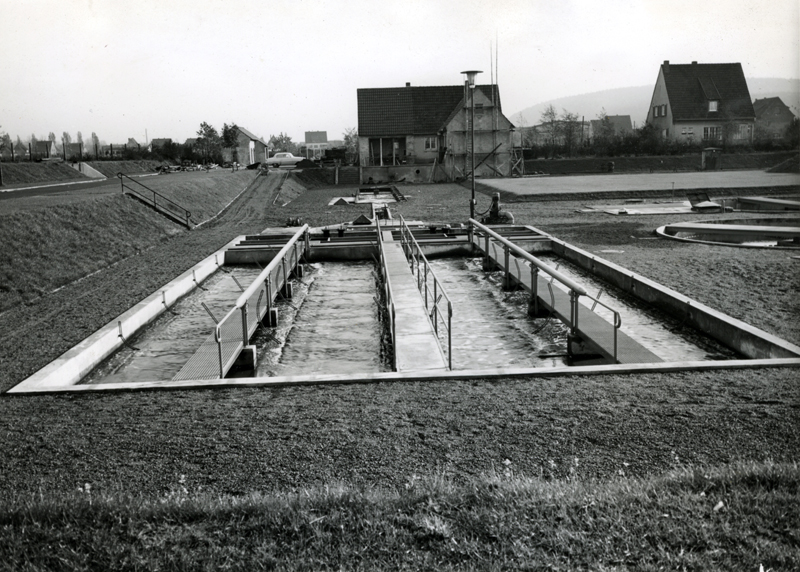

Another mechanical process is the use of grit chambers in order to catch the mineral matter carried especially by rain. The first grit chambers were simple rectangular or round dips, usually with a steep bed slope to facilitate the removal of settleable solids (which was done manually using various receptacles and later with travelling cranes or grab dredgers). The longitudinal grit chamber in Essen is a continuation of the first tank systems. The settling of solids is achieved by widening the cross-section of the settling channel, thereby reducing flow velocity. The deep grit chamber with a vertical flow was developed in the 1930s. Due to the poor retention characteristics of fine sand, deep grit chambers are no longer in use today. The aerated grit chamber which was developed between around 1950 and 1960 is a fairly recent development.

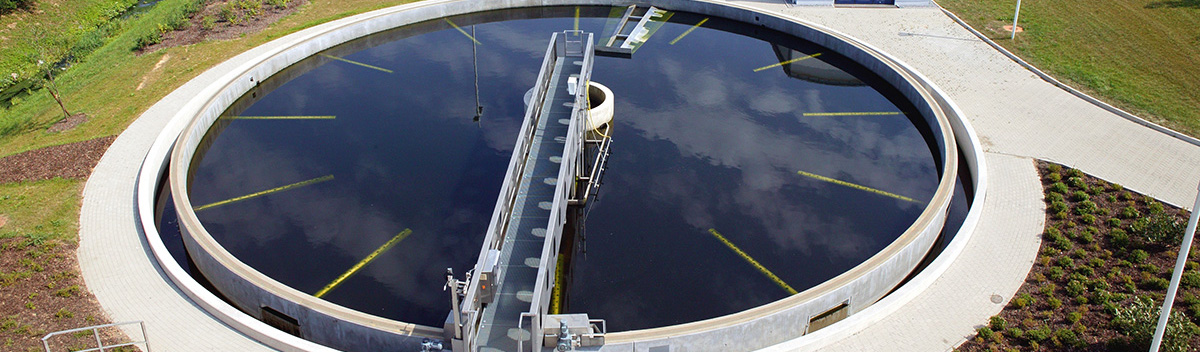

Settling tanks reducing flow velocity to such an extent that suspended solids can settle at the bottom were known even in ancient civilisations. In England, rectangular settling tanks were operated intermittently from 1850, meaning that the sewage inflow had to be stopped regularly for sludge removal. In the first decade of the 20th century, studies of the effects of sludge volume and composition on flow velocity provided a scientific foundation for the settlement method and allowed for a drastic reduction in the size of settling tanks. The invention of the so-called “Fidler spiral“, a rotating sludge scraper for circular tanks, marked the beginning of the development of various scraper installations for the removal of sludge.

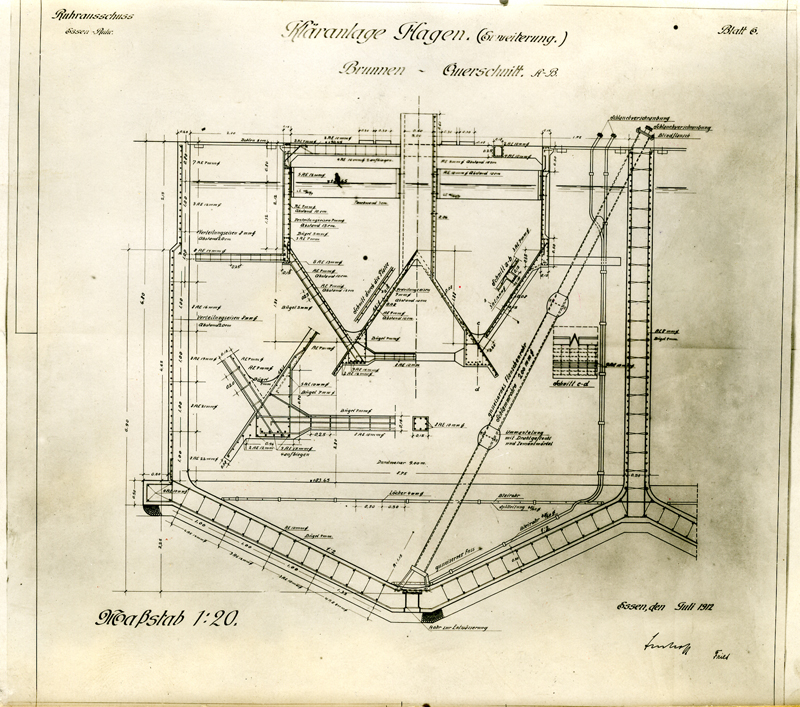

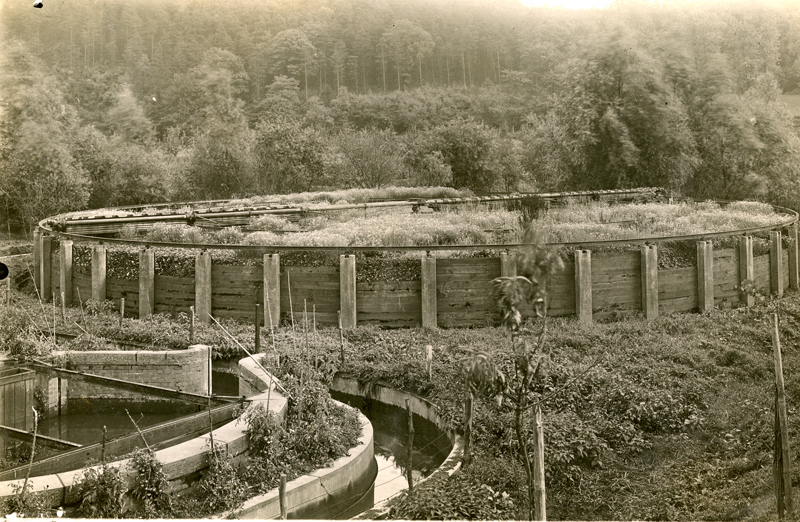

From around 1880, upflow settlement tanks such as the “Dortmund tank” constituted a completely different approach. Having been designed specifically to allow for a continuous feed of waste water, these tanks did not have to be emptied for sludge removal. Another development of this technology is the hopper-bottomed tank which is also designed for a vertical flow. Hopper-bottomed tanks are well-suited for purifying flocculated sludge in precipitation processes or for post-biological treatment. In those processes, similar equipment is used to this day.

Since settling tanks and upflow settlement tanks have to be installed well underground at considerable setting-up costs, the early 20th century also saw experiments with above-ground sewage treatment towers and tanks.

One problem the pioneers of sewage treatment had to deal with was the onset of digestion processes in the sludge which hampered further settlement and potential downstream biological treatment. For that reason, US chemist Clark developed the idea to physically separate settlement and digestion processes. In 1903, his idea was partially implemented in the so-called Travis tank; in 1906, Karl Imhoff managed to run both processes separately within the same two-storey building. The tank he designed was first used by the Emscher cooperative and has come to be known as "Emscher tank" or "Imhoff tank". Thanks to their simple design and low operating costs, Imhoff tanks were soon widely used.

Biological treatment

In the early days of biological sewage treatment, natural processes such as ground treatment, i.e. large-surface application of sewage to soil, or catching waste water in sewage lagoons were very common. Besides aiming at purifying waste water, there was usually also a business background to this type of treatment. People wanted to utilise the waste water nutrients for farming or for sewage fish ponds.

Over time, these natural processes were developed into artificial biological processes such as trickling filters, biological contactors, and eventually the activated sludge treatment. This advance development of natural biological processes became necessary as metropolitan areas soon no longer provided open areas sufficiently large for irrigation fields or sewage lagoons.

The activated sludge process was developed in Boston in 1912. It was a close imitation of the biological self-purification processes which naturally occur in a river. In the so-called "activated" sludge, natural scouring organisms are enriched. Continuous aeration was required to avoid a lack of oxygen. Compared to other types of biological treatment, the activated sludge process showed quite a high cleaning rate.

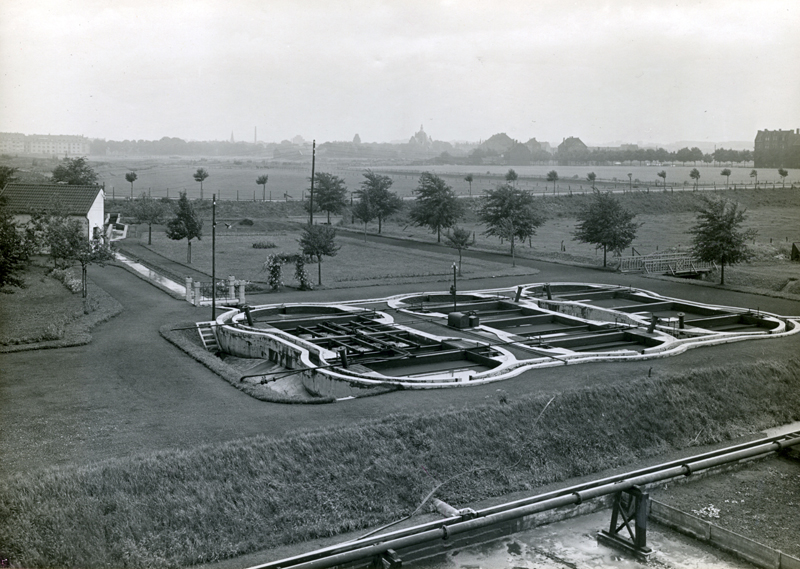

The first biological sewage treatment plant in mainland Europe to apply the activated sludge treatment was the Essen-Rellinghausen plant where this new technology was brought to maturity by Karl Imhoff.

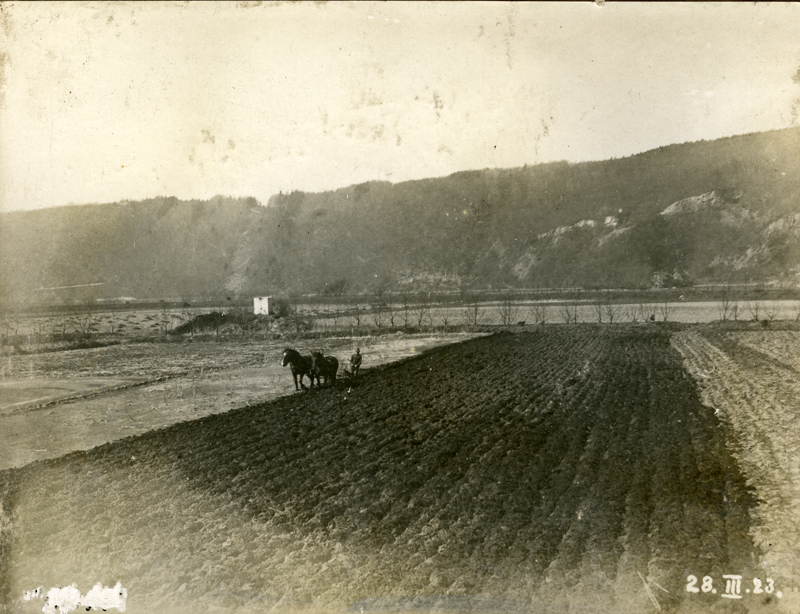

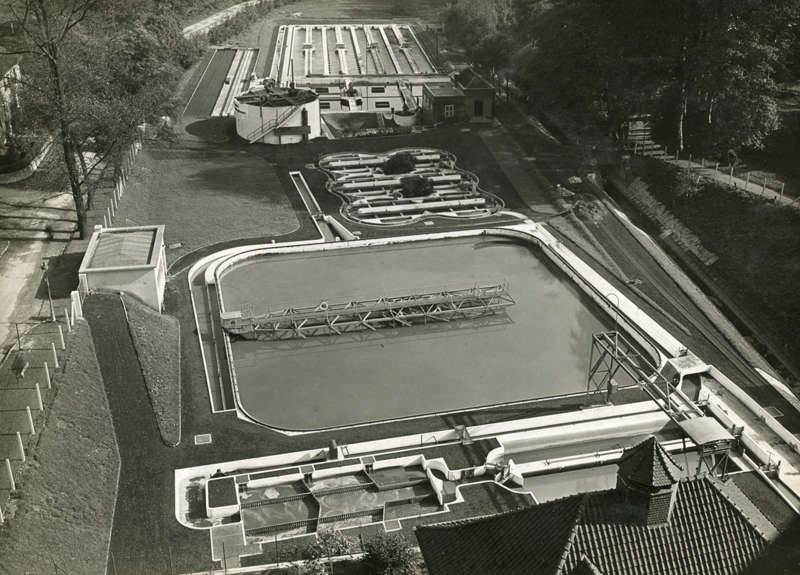

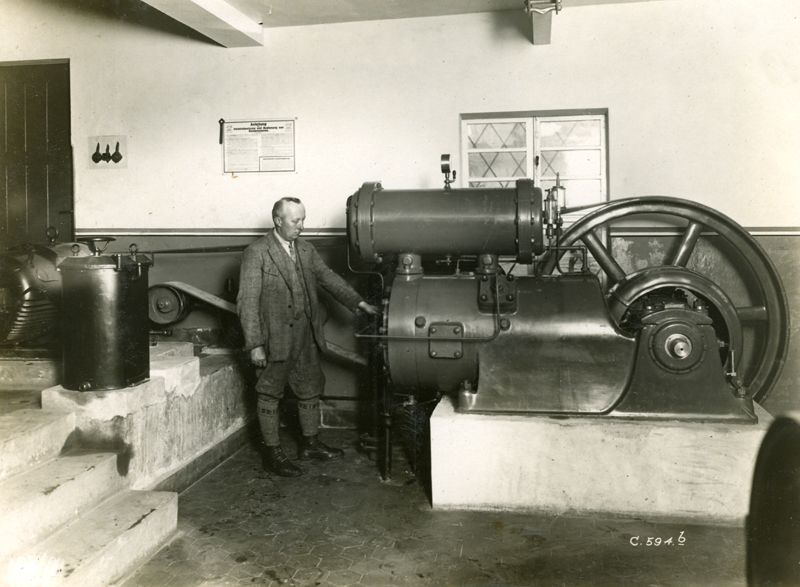

The Rellinghausen sewage treatment plant was built by the City of Essen in 1912 and acquired by the Ruhrverband in 1914. Water treatment in this plant which was originally designed for 22,000 inhabitants initially took place in Imhoff tanks. However, as soon as the early 1920s, their cleaning rate was no longer sufficient as the water purified in Rellinghausen was fed into the River Ruhr near the municipal water catchment area. Hence, construction of a large aeration plant started in May 1925. The new plant was designed for 45,000 inhabitants and thus had more than twice the size of the original Imhoff tank plant. In addition, due to the inflow of pit water from mining, the plant was designed to allow for a sewage flow four times bigger than was common at the time: 600 litres per capita per day. In December 1925, the first aeration plant in mainland Europe took up operation. It was shut down in 2005 after completion of the South Essen sewage treatment plant.

Chemical treatment by precipitation

Chemical precipitation processes are amongst the oldest methods in sewage treatment. The first plant where waste water was purified using lime opened in Birmingham in 1872. Chemical precipitation was at its height in England, where around 200 plants were built between 1880 and 1890, and in America. In chemical precipitation, adding chemical compounds to the water causes dissolved solids to precipitate and allows them to be removed from settlement tanks along with the sludge. The most frequently used chemicals were lime, aluminium salt, and iron salt. These processes being complicated and expensive, however, they were replaced almost entirely by biological processes from 1890.

Today, chemical processes are used almost exclusively for removing phosphate compounds occurring e.g. in laundry liquids.

Sludge treatment processes

Whatever the method, mechanical, biological, or chemical: any sewage treatment process will generate sludge which has to be treated and disposed of.

The first sludge treatment methods were to create sludge lagoons and trenches. Previously excavated trenches would be filled with liquid sludge and covered with earth; the sludge would drain and be decomposed by soil organisms. Digested sludge did not need to be covered, thereby accelerating loading rates.

While sludge trenches were used mainly for screenings, the fine sludge from settling tanks was disposed of primarily in sludge lagoons. These were natural or artificial earth basins into which liquid sludge was pumped in order to let it drain and digest. The disadvantage of both lagoons and trenches was the large surface required and the bad smell.

In order to cope with the problem of odour nuisance caused by wet, non-digested sludge, various sludge dewatering techniques were developed. Filter presses that would dewater the sludge by means of applying strong pressure were already used around 1880.

After World War II, the processes to improve dewatering characteristics were taken a step further. Sludge thickening aimed at increasing total solids through static thickening or centrifuge thickening. Sludge conditioning was to increase dewatering characteristics by adding precipitation and flocculation agents, or by applying heat treatment. Finally, sludge stabilisation is still in use today; its large oval digesters are visible from far afield. This process mainly helps to decompose the organic and often odorous sludge components and to improve its hygienic characteristics.